24 Oct 2014

21 Nov 2013

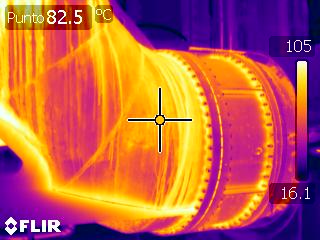

KeelWit analyzes energy consumption improvement possibilities at a municipal solid waste plant

KeelWit has commenced a study of the entire process of collection, waste handling, separation and final energy generation at Municipal Solid Waste Facility, given that the industry has a major component of thermal energy in its process. Recycling processes involve high temperatures and a complex heat recovery system, ash management and combustion control, due to the heterogeneous nature of municipal solid waste. Any process in which high temperatures are reached and large volumes of materials are involved is usually susceptible to energy consumption improvements, better use of residual heat, performance enhancements and a new set point definition of its KPIs. These improvements can be achieved by changes in production volumes (downwards or upwards) that, over the years, have displaced actual operating conditions from initial set points. All ovens, Heat Recovery System Generators, turbines, absorbers, filters, catalytic tanks and chimneys are a perfect environment for applying the KeelWit Energy Methodology of Optimization...18 Oct 2013

KeelWit concludes project on energy efficiency improvements in an industrial plant

KeelWit has concluded a project designed to improve energy efficiency at a chemical plant, through several changes made to the main processes of the plant. After a comprehensive analysis of its pirotubular boilers, thermo compressors/ejectors and condensers, areas of improvement were identified and evaluated, priorities established and suppliers selected for the implementation of the enhancement plan. The final project results will bring a substantial reduction in vapour, gas and power consumption and a Return On Investment within less than 1...25 Jan 2013

KeelWit starts a project on a CHP PLANT

KeelWit is working on the improvement of the energy efficiency of a combined heat and power plant, selecting the areas where a heat transfer with colder flows is feasible and designing the necessary heat exchanger system required, as well as improving the aerodynamics of certain pipelines where the pressure drop can be reduced....10 Jan 2013