1 Jan 2014

21 Nov 2013

KeelWit analyzes energy consumption improvement possibilities at a municipal solid waste plant

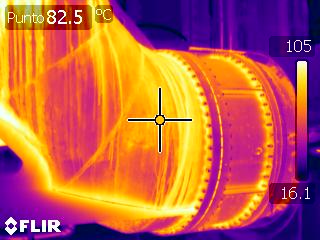

KeelWit has commenced a study of the entire process of collection, waste handling, separation and final energy generation at Municipal Solid Waste Facility, given that the industry has a major component of thermal energy in its process. Recycling processes involve high temperatures and a complex heat recovery system, ash management and combustion control, due to the heterogeneous nature of municipal solid waste. Any process in which high temperatures are reached and large volumes of materials are involved is usually susceptible to energy consumption improvements, better use of residual heat, performance enhancements and a new set point definition of its KPIs. These improvements can be achieved by changes in production volumes (downwards or upwards) that, over the years, have displaced actual operating conditions from initial set points. All ovens, Heat Recovery System Generators, turbines, absorbers, filters, catalytic tanks and chimneys are a perfect environment for applying the KeelWit Energy Methodology of Optimization...11 Apr 2013

KeelWit Technology, technological partner of ALTRAN INNOVATION

ALTRAN INNOVACIÓN is a part of the Altran Group, global leader in innovation and high-tech engineering. An international group with over 20,000 employees in 2013, Altran operates in twenty countries throughout Europe, Asia and the Americas. ALTRAN is active in every hi-tech sector, allowing itself to offer global solutions to its customers. The agreement signed by both companies presents KeelWit as ALTRAN’s Technological Partner, reinforcing ALTRAN’s competence in energy efficiency technologies. Both companies shall jointly apply KEEMO (KeelWit Energy Efficiency Method of Optimization) in ALTRAN’s customers. The proven trust of ALTRAN in the robustness of this methodology, developed by KeelWit for industrial processes modeling and energy consumption optimization, means a strong backup for the work deployed during 2 years for its...25 Jan 2013

KeelWit starts a project on a CHP PLANT

KeelWit is working on the improvement of the energy efficiency of a combined heat and power plant, selecting the areas where a heat transfer with colder flows is feasible and designing the necessary heat exchanger system required, as well as improving the aerodynamics of certain pipelines where the pressure drop can be reduced....10 Jan 2013